Maximizing Storage Efficiency: Innovative Warehousing Website Design Solutions

In the fast-paced world of logistics, maximizing storage efficiency is paramount for warehousing operations. Innovative website design solutions can play a crucial role in enhancing the functionality and effectiveness of warehousing strategies. This article delves into various methods and tools that can optimize storage space, improve inventory management, and ensure safety and compliance, all while maintaining cost-effectiveness. Whether it’s through vertical space utilization, cube storage, or dynamic warehouse design, these solutions offer a pathway to transforming the way warehouses operate.

Key Takeaways

- Employing vertical space strategies, such as varied shelving heights and mezzanine systems, can significantly increase storage capacity without expanding the warehouse footprint.

- Cube storage systems offer a modular design that increases storage density, which is particularly beneficial for urban micro-fulfillment centers.

- Dynamic warehouse designs with multi-level racking systems and adjustable layouts can adapt to changing inventory needs, enhancing space utilization.

- Safety and compliance are integral to storage efficiency, with solutions focusing on efficient space utilization and improved inventory management.

- Optimizing load distribution involves employing customizable storage solutions and utilizing warehouse layout planning tools for better operational efficiency.

Strategies for Maximizing Vertical Space

Analyzing Current Space and Inventory

Before embarking on a journey to maximize storage efficiency, it’s crucial to conduct a thorough analysis of the current space and inventory. This initial step lays the groundwork for identifying potential improvements and designing a more efficient warehousing system.

- Review current storage practices and pinpoint areas that require enhancement.

- Examine the physical characteristics of your inventory, considering how they influence storage needs.

- Utilize warehouse layout planning tools to assess and visualize the space.

By meticulously analyzing the existing setup, businesses can uncover inefficiencies and devise strategies to optimize their warehousing operations.

After the analysis, it’s important to keep track of the effectiveness of any changes made. Regularly monitoring KPIs such as space utilization and inventory accuracy will inform the success of the implemented strategies. Remember, optimization is an ongoing process that benefits from continuous refinement and adaptation.

Designing an Optimal Layout

Designing an optimal layout is crucial for maximizing storage efficiency and workflow within a warehouse. Modern planning tools, such as warehouse management systems (WMS) and computer-aided design (CAD) software, are invaluable for this task. These tools enable managers to visualize potential layouts, simulate workflows, and assess the impact of different load distribution strategies before making any physical changes.

Effective load distribution takes into account the accessibility of items and the overall workflow. Strategic placement of frequently used items in accessible locations reduces travel time and increases picking efficiency. Additionally, optimizing the flow of goods from receiving to shipping minimizes congestion and enhances productivity.

To ensure a well-balanced warehouse layout, consider the following steps:

- Review current storage practices and identify areas for improvement.

- Utilize planning tools to create a balanced design, focusing on even weight distribution and maximizing vertical space.

- Place frequently used items in easily accessible locations to streamline picking processes.

- Design the layout to minimize congestion and facilitate a smooth flow of goods from receiving to shipping.

Implementing Varied Shelving Heights and Mezzanine Systems

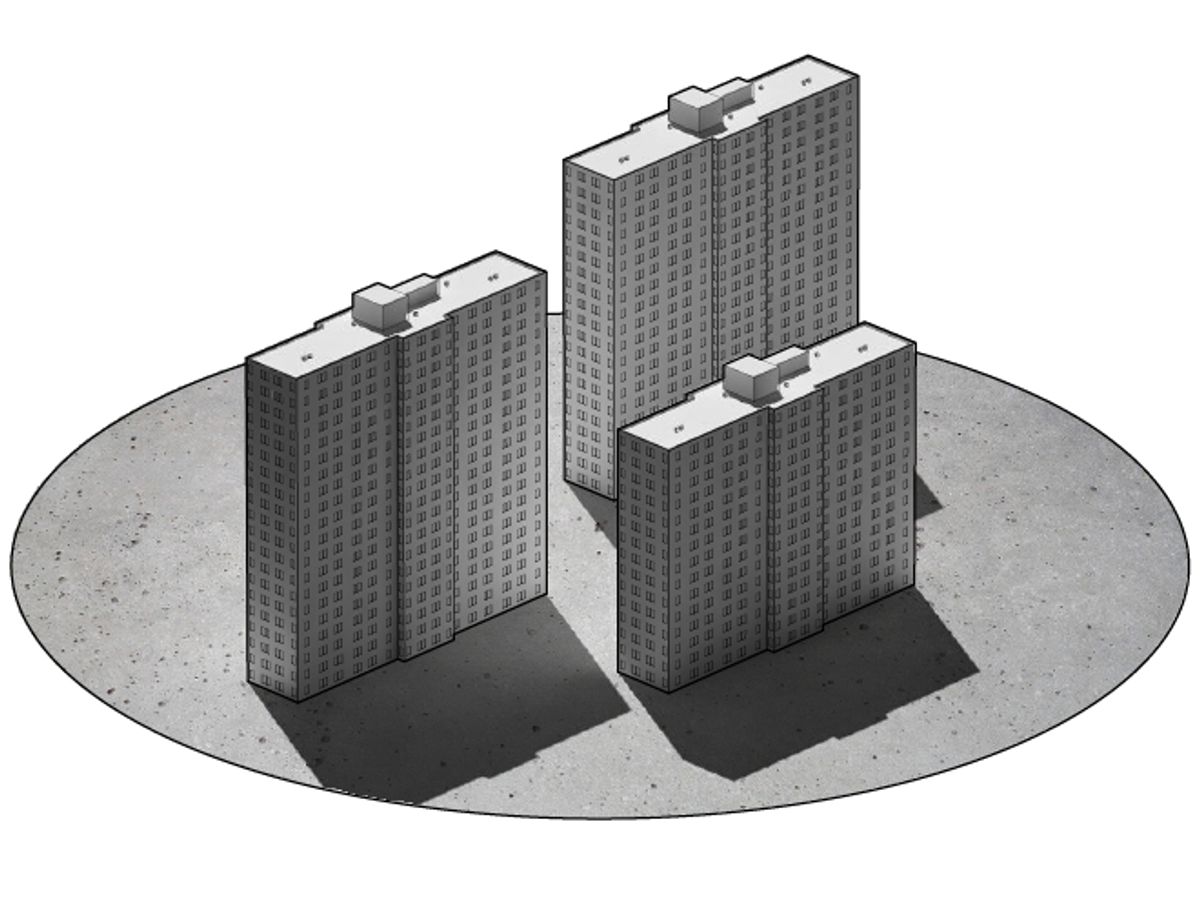

To fully exploit the vertical dimension of warehousing, implementing varied shelving heights and mezzanine systems is essential. These systems allow for the stacking of goods in a manner that maximizes space vertically, which is particularly beneficial for warehouses with limited floor space. Careful planning is required to maintain stability and accessibility, especially for items stored at higher levels.

- Shelving Solutions: Space Maker Designs offers a range of shelving options to ensure optimal load distribution. Modular shelving can be adjusted to fit various inventory sizes, and it’s crucial to consider factors like weight capacity and adjustability.

- Mezzanine Systems: By adding a mezzanine level, warehouses can double or even triple their usable space. This is an effective way to expand storage capacity without increasing the building’s footprint.

Customizable storage solutions and slotting optimization are key to managing a diverse range of inventory specifications. By strategically placing items based on dimensions and access frequency, warehouses can achieve better load distribution and operational efficiency.

Cube Storage: A Game-Changer for Urban Warehousing

Increasing Storage Density with Modular Design

The advent of cube storage has revolutionized the warehousing industry, particularly in urban settings where space is at a premium. By adopting a modular design, warehouses can achieve a significant increase in storage density. This is not just about stacking more products; it’s about creating an environment that can adapt to the diverse needs of inventory while maintaining efficiency and accessibility.

Cube storage systems are designed to be highly adaptable, catering to the varying sizes and shapes of products. They enable warehouses to utilize vertical space more effectively, which is essential for urban micro-fulfillment centers that operate within limited square footage.

Here are some benefits of modular cube storage:

- Enhanced inventory management: With a more organized layout, inventory tracking and order picking become faster and more accurate.

- Space optimization: Cube storage can increase inventory capacity by up to 400%, making it a game-changer for space-constrained warehouses.

- Flexibility: Adjustable shelving and racking accommodate different product dimensions, ensuring efficient use of space.

By integrating cube storage into their design, warehouses can not only improve their storage capabilities but also address the challenges of load distribution. This is particularly important for items that vary greatly in size and weight, as modular systems allow for a more uniform distribution across the storage area.

Enhancing Inventory Management and Order Picking

Efficient inventory management and order picking are pivotal to the success of urban warehousing. Real-time tracking of inventory ensures that high-demand items are strategically placed closer to picking areas, streamlining the retrieval process. This not only maximizes space but also significantly reduces the time taken to fulfill orders.

The implementation of advanced Warehouse Management Systems (WMS) has been a game-changer. These systems offer a suite of features that enhance the precision and speed of warehouse operations:

- Inventory Visibility: Real-time tracking of inventory across multiple locations.

- Order Management: Automated picking, packing, and shipping with efficient order fulfillment workflows.

- Reporting and Analytics: Insights into operations, inventory levels, and staff performance.

- Integration Capabilities: Seamless integration with existing ERP, CRM, and supply chain management systems.

- Scalability: The ability to support business growth without needing a system overhaul.

The precision of live data capture is a significant upgrade over past methods, allowing for meticulous stock level tracking and substantially diminishing the risks associated with overstocking or depletion.

By leveraging cloud-based solutions, warehouses can revolutionize logistics management, offering scalability, cost efficiency, security, and collaboration. These solutions are particularly beneficial during critical, high-activity periods, where the risks of overstocking or stock depletion are most pronounced.

Adapting to Micro-Fulfillment Center Needs

The rise of micro-fulfillment centers (MFCs) is a testament to the evolving landscape of urban warehousing. These compact, strategically located facilities are revolutionizing the way businesses handle online grocery shopping, offering rapid delivery services that cater to the modern consumer’s expectation for speed and convenience.

By integrating MFCs into urban settings, such as shopping malls, companies are not only reducing last-mile delivery costs but also addressing the consumer’s aversion to long waits. This shift is particularly significant in the grocery sector, where efficiency is paramount.

The implementation of automation technologies, like the AutoStore system, is enhancing inventory accuracy and labor efficiency, which is crucial in an industry facing a labor deficit. The adaptability of MFCs allows for the management of peak periods and the introduction of new product ranges without the need for extensive physical expansions.

MasteringAgency.com is at the forefront of this transformation, providing logistics companies with the necessary web design and marketing tools to thrive in a competitive market.

Dynamic Warehouse Design for Adaptable Space Utilization

Employing Multi-Level Racking Systems

To overcome the challenge of limited physical space, warehouses are increasingly turning to multi-level racking systems. These systems capitalize on vertical space, allowing for a significant increase in storage capacity without expanding the warehouse’s footprint. By integrating mezzanine flooring, warehouses can create additional levels of storage, effectively doubling or even tripling the usable space.

The selection of racking solutions should be tailored to the specific needs of the warehouse. For instance:

- Selective racks provide flexibility for a diverse product range.

- Pallet racking systems are better suited for heavier items.

- Cantilever racks are ideal for storing long, bulky items.

- Modular shelving offers adjustability for varying inventory sizes.

Employing multi-level racking systems not only maximizes space but also promotes efficient load distribution. This approach extends the lifespan of storage units and floors, reduces maintenance costs, and enhances worker safety by facilitating easier access to stored items.

Adjusting Layouts for Changing Inventory

In the dynamic environment of warehousing, inventory profiles can shift rapidly, necessitating adaptable layout designs. Adjusting warehouse layouts to accommodate changing inventory is crucial for maintaining operational efficiency and storage optimization. This process involves regular reviews of inventory characteristics and the implementation of flexible storage solutions.

- Regularly review inventory profiles to identify changes in size, weight, or volume.

- Utilize adjustable racking systems to reconfigure storage spaces quickly.

- Incorporate modular components that can be easily expanded or reduced.

- Ensure that layout adjustments maintain safe and accessible pathways for staff.

By proactively adjusting layouts, warehouses can respond to market demands and seasonal fluctuations without compromising on space utilization or accessibility.

The goal is to create a warehouse that can evolve with its inventory, seamlessly integrating new products and phasing out obsolete ones without the need for extensive overhauls. This strategic flexibility not only saves time but also reduces the costs associated with static storage systems.

Leveraging Drop-Shipping and Customizable Storage Solutions

In the realm of warehousing, flexibility is paramount. Customizable storage solutions, such as adjustable shelving and modular racking, are essential for accommodating a diverse range of inventory specifications. By leveraging drop-shipping, businesses can minimize their on-hand inventory, reducing the need for extensive storage space and allowing for a more dynamic use of the warehouse.

The integration of drop-shipping models with customizable storage solutions provides a dual advantage: it optimizes space utilization and aligns with the just-in-time inventory practices that modern businesses strive for.

To further enhance warehouse efficiency, consider the following steps:

- Assess the variability of your inventory to determine the need for adjustable storage systems.

- Implement slotting optimization to ensure strategic placement of items based on size and access frequency.

- Explore partnerships with companies like Mastering Agency, which specialize in innovative web solutions that support logistics and storage efficiency.

Ensuring Safety and Compliance in Storage Efficiency

Efficient Space Utilization

In the quest to maximize storage efficiency, efficient space utilization is paramount. By optimizing every square foot of storage space, businesses can minimize wastage and enhance operational efficiency. This approach not only reduces storage costs but also streamlines the process of locating and accessing inventory.

- Analyze Current Space and Inventory: Assess storage practices and pinpoint areas for improvement.

- Design an Optimal Layout: Employ warehouse layout planning tools for a space-maximizing design.

- Implement Space Maker Designs: Integrate solutions that unlock efficiency and adaptability in storage.

Emphasizing efficient space utilization translates to a more adaptable storage environment, capable of responding to varying inventory needs without the need for extensive reorganization.

Improved Inventory Management

Efficient inventory management is pivotal for maintaining a streamlined warehouse operation. Advanced inventory management systems (IMS) provide real-time data on stock levels, locations, and movements, which is essential for balanced inventory distribution. This prevents overloading in certain areas and facilitates a more efficient picking and packing process.

By optimizing inventory turnover and preventing stockouts or overstocking, businesses can significantly reduce holding costs and enhance supply chain efficiency.

The integration of IMS with warehouse management systems (WMS) allows for increased flexibility and scalability, adapting to the changing demands of the warehouse. This integration is a key factor in ensuring that inventory is managed effectively:

- Real-time monitoring of stock levels

- Streamlined operations and reduced holding costs

- Proactive stock management to prevent stockouts

In contrast, traditional warehousing that relies on manual processes can lead to errors and inefficiencies, negatively impacting customer satisfaction and operational efficiency.

Cost-Effective and Flexible Storage Solutions

In the quest for maximizing storage efficiency, cost-effective and flexible storage solutions are paramount. Businesses are increasingly seeking out warehousing options that not only fit their budget but also provide the adaptability required to respond to market changes.

WELPL’s offerings exemplify this trend, with a variety of cost-efficient options such as bulk and shared warehousing. These solutions are designed to optimize resource allocation and streamline operations, thereby reducing overhead costs without sacrificing service quality.

Recognizing the need for versatility, warehousing services now offer flexible storage options to cater to different inventory volumes. This flexibility ensures that businesses can scale up or down as needed, accommodating everything from seasonal peaks to long-term storage demands.

- Increased Flexibility and Scalability

- Several Storage Options Available

These flexible solutions not only meet the dynamic needs of modern commerce but also allow for a more strategic approach to inventory management. By leveraging such adaptable warehousing strategies, businesses can maintain a competitive edge in the ever-evolving marketplace.

Tools and Techniques for Optimizing Load Distribution

Customizable Storage Solutions for Diverse Inventory

In the realm of warehousing, inventory can vary significantly in size, shape, and weight, which presents a challenge for maintaining uniform load distribution. Customizable storage solutions are essential for addressing this diversity. Adjustable shelving and modular racking systems allow for the accommodation of a wide range of inventory specifications, ensuring that each item is stored efficiently and accessibly.

To further optimize warehouse operations, businesses should consider implementing a slotting optimization process. This strategy involves placing items based on their dimensions and frequency of access, which enhances load distribution and operational efficiency.

Selecting the right storage solutions is crucial for adapting to the ever-changing demands of commerce. Shelving and racking systems should not only be suited to current inventory types but also offer the flexibility to adjust as inventory evolves. Coupled with advanced inventory management systems, these customizable solutions provide the backbone for a dynamic and responsive warehousing environment.

Slotting Optimization for Enhanced Efficiency

Slotting optimization is a critical component in the quest for warehouse efficiency. By strategically placing items based on their dimensions and frequency of access, warehouses can achieve a more uniform load distribution and operational efficiency. This process not only streamlines the workflow but also reduces labor costs and accelerates order fulfillment, leading to enhanced customer satisfaction.

Slotting optimization enables businesses to minimize wasted space and maximize storage capacity, directly impacting ROI.

The implementation of slotting optimization can be broken down into a series of steps:

- Analyzing inventory characteristics such as size, shape, and weight.

- Categorizing items based on picking frequency and handling requirements.

- Designing a slotting plan that aligns with the warehouse’s operational workflow.

- Continuously reviewing and adjusting the slotting arrangement to adapt to changes in inventory or demand patterns.

Utilizing Warehouse Layout Planning Tools

The integration of advanced warehouse layout planning tools is pivotal in orchestrating an efficient load distribution strategy. Modern software solutions, such as Warehouse Management Systems (WMS) and Computer-Aided Design (CAD) programs, empower managers to meticulously craft and evaluate potential warehouse layouts. These tools facilitate the simulation of workflows, enabling the preemptive identification and resolution of bottlenecks, and the optimization of goods movement within the facility.

By leveraging these sophisticated planning tools, warehouses can significantly enhance operational efficiency, ensuring that every square inch of space is utilized to its maximum potential.

Key steps in utilizing these tools include:

- Analyzing current space and inventory to pinpoint areas ripe for enhancement.

- Designing an optimal layout that balances weight distribution and maximizes vertical space, while maintaining accessibility to high-turnover items.

- Assessing the impact of various load distribution strategies through simulation to make informed decisions before actual implementation.

The ultimate goal is to achieve a harmonious balance between maximizing storage capacity and maintaining a seamless workflow. This balance is crucial for reducing operational costs, improving safety, and boosting overall warehouse productivity.

In the fast-paced world of logistics, optimizing load distribution is key to staying ahead of the competition. Our award-winning team at MasteringAgency.com specializes in providing tailored web design and marketing solutions that can transform your logistics operations. Don’t let outdated strategies weigh you down. Elevate your business today by visiting our website and scheduling your free consultation. Let’s work together to streamline your load distribution and drive your business forward.

Conclusion

In conclusion, the innovative warehousing website design solutions discussed throughout this article provide a comprehensive blueprint for maximizing storage efficiency. By embracing strategies such as maximizing vertical space, analyzing current space and inventory, leveraging cube storage, and optimizing load distribution, warehouses can significantly enhance their operational efficiency. The integration of customizable storage solutions and the use of warehouse layout planning tools are pivotal in addressing the diverse challenges of inventory management. As businesses continue to adapt to the evolving demands of storage and distribution, these innovative solutions pave the way for improved safety, reduced costs, and a more dynamic and responsive warehousing environment. It is clear that with the right approach and tools, warehouses can transform their space into a strategic asset, driving success and sustainability in today’s competitive market.