Streamlining Operations: How Cutting-Edge Websites Are Revolutionizing Efficient Supply Chain Management

In the rapidly evolving business landscape, streamlining supply chain management is a critical factor for success. As companies face the challenges of market fluctuations and customer demands, the integration of cutting-edge websites and technologies offers transformative solutions. These advancements not only improve operational efficiencies but also foster agile and responsive supply chains capable of adapting to change. This article delves into how innovative web technologies are revolutionizing efficient supply chain management, highlighting key strategies for optimizing operations from procurement to delivery.

Key Takeaways

- Advanced analytics and AI are pivotal in forecasting demand and automating supply chain processes, leading to significant efficiency gains.

- Real-time tracking and cloud-based platforms enhance visibility and supplier collaboration, enabling quicker response to market changes.

- Inventory optimization through lean principles and predictive analytics reduces waste and ensures optimal stock levels.

- E-commerce integration, including omnichannel fulfillment and dropshipping, streamlines order processing and reduces inventory costs.

- Continuous improvement and agile methodologies, exemplified by Zara’s supply chain, are essential for adapting to the dynamic business environment.

Innovative Technology Integration in Supply Chain Management

Adopting Advanced Analytics for Demand Forecasting

The integration of advanced analytics into supply chain management has become a game-changer for demand forecasting. Accurate predictions of customer demand are now possible through the analysis of historical data, market trends, and various external factors. This precision allows companies to optimize inventory levels, reduce carrying costs, and avoid stockouts or excess inventory.

- Key Benefits of Advanced Analytics:

- Enhanced accuracy in demand predictions

- Ability to identify and respond to market trends

- Improved collaboration across the supply chain

By embracing data analytics and predictive modeling, businesses gain valuable insights that drive supply chain optimization. Predictive analytics not only forecasts demand but also anticipates potential disruptions, enabling proactive measures to minimize impact.

For instance, an electronics manufacturer might analyze historical sales data alongside weather patterns to adjust inventory during peak seasons. Similarly, a beverage company could work with retailers to predict summer demand, tweaking production and distribution to meet it efficiently. These examples underscore the transformative impact of advanced analytics on supply chain management.

Implementing Real-Time Tracking for Enhanced Visibility

The integration of real-time tracking technologies is a game-changer for supply chain management. By utilizing GPS, RFID, and IoT devices, businesses can achieve unprecedented levels of visibility and control over their shipments. This not only streamlines operations but also provides critical data that can be used to optimize logistics processes.

Real-time visibility and data integration revolutionize logistics operations, enhancing decision-making, operational control, and customer experiences.

The benefits of implementing advanced tracking systems are manifold:

- Enhanced operational transparency: Knowing the exact location and status of goods at all times.

- Proactive issue resolution: Quickly identifying and addressing potential delays or problems.

- Data-driven decision making: Leveraging the data collected for strategic planning and continuous improvement.

In the context of customer satisfaction, the ability to track shipments in real time significantly reduces instances of lost or delayed shipments, thereby improving the overall customer experience. Automation in tracking also drives efficiency and cost reduction, which are critical for maintaining a competitive edge in today’s market.

Leveraging AI and Machine Learning for Process Automation

The integration of AI and Machine Learning (ML) into supply chain management is a game-changer, automating tasks that were once manual and error-prone. AI algorithms excel in analyzing vast datasets, uncovering patterns that lead to more informed decision-making and predictive capabilities. This not only enhances efficiency but also significantly reduces operational costs.

- AI-powered chatbots and virtual assistants provide instant customer service, improving satisfaction and freeing up human resources.

- Autonomous vehicles and drones, equipped with AI, optimize transportation routes and delivery times.

- Robotic process automation (RPA) streamlines warehouse operations, from storage to picking systems, ensuring faster order fulfillment.

By embracing AI and ML, companies are not only automating processes but also setting the stage for continuous innovation and improvement in supply chain management. The predictive power of these technologies allows for a proactive approach to demand forecasting and inventory control, ensuring that supply chains are not just efficient, but also resilient and adaptable to changing market conditions.

Optimizing Supplier Collaboration and Management

Building Strong Supplier Relationships

In the realm of supply chain management, building strong supplier relationships is a cornerstone for achieving operational excellence. These relationships are not just transactional; they are strategic partnerships that can lead to significant improvements in efficiency and cost savings. For instance, companies that engage in regular communication and joint planning with their suppliers often experience more timely deliveries and better alignment of business objectives.

By fostering collaborative partnerships, organizations can tap into a wealth of benefits, including enhanced communication, shared risk management, and mutual growth opportunities. This collaborative approach is exemplified by leading companies like Apple, which attributes much of its supply chain success to the close collaboration with its suppliers.

Here are some key benefits of strong supplier relationships:

- Improved communication and trust

- Timely and reliable deliveries

- Cost savings through joint planning

- Access to new technologies and market insights

- Enhanced product quality and customer satisfaction

Efficient supplier collaboration, warehouse optimization, and technology integration are pivotal in enhancing supply chain management. These elements work in tandem to deliver cost efficiency, customer satisfaction, and a competitive edge in today’s dynamic market.

Utilizing Vendor Managed Inventory (VMI)

Vendor Managed Inventory (VMI) is a transformative approach where suppliers take the reins of managing their products’ inventory levels at the customer’s location. This shift in responsibility enables a more synchronized supply chain, ensuring that stock is replenished efficiently and in alignment with actual demand.

The benefits of VMI are numerous, including reduced inventory carrying costs, minimized stockouts, and enhanced partnership between suppliers and customers. By allowing suppliers to monitor and manage stock levels, businesses can achieve a leaner inventory with fewer excesses and obsolescence.

- Enhanced inventory visibility ensures that all stakeholders have access to accurate stock information.

- Advanced inventory management solutions like VMI and automatic reports optimize stock levels. Key features include product categorization, supplier tools, and customized reporting for efficient logistics operations.

With VMI, companies can focus on their core competencies while suppliers ensure that inventory levels are optimized and aligned with consumption patterns.

Enhancing Communication with Cloud-Based Platforms

The integration of cloud-based platforms has been a game-changer for enhancing communication within the supply chain. These platforms facilitate a more cohesive approach to managing operations, allowing for real-time data sharing and collaboration among all stakeholders. For instance, an automotive manufacturer that connects its design, production, and procurement teams through a cloud system can significantly reduce lead times and improve product quality.

Effective coordination in the supply chain ensures seamless operations, efficient resource use, and customer satisfaction. By leveraging digital communication channels such as chat platforms and project management tools, companies can overcome the limitations of traditional methods like emails and phone calls, which are often slower and more prone to misinterpretation.

The rise of remote work has made virtual collaboration tools indispensable. Video conferencing, document sharing, and project management platforms are now vital in keeping remote teams connected and productive.

Cross-functional teams and interdepartmental communication are crucial for supply chain success. By breaking down silos and fostering open communication, these teams can respond swiftly to demand fluctuations, allocate resources efficiently, and prevent stockouts, especially during peak seasons when scalability and secure remote access are essential.

Inventory Optimization Strategies

Applying Lean Inventory Principles

Lean inventory principles are pivotal in achieving a streamlined supply chain. By reducing waste and improving efficiency, companies can significantly cut costs and enhance their operational performance. A just-in-time (JIT) inventory system exemplifies this approach, where materials are ordered and received only as they are needed in the production process, thereby reducing inventory costs and minimizing storage needs.

Key aspects of lean inventory include:

- Minimizing overproduction to avoid excess stock

- Reducing waiting times and lead times

- Streamlining processes to eliminate unnecessary steps

- Improving layout and efficiency of warehouse operations

Embracing lean inventory principles not only optimizes the use of resources but also aligns closely with environmental sustainability by reducing the carbon footprint associated with overproduction and excess inventory.

The table below illustrates the impact of lean inventory practices on key performance indicators:

| Indicator | Before Lean Implementation | After Lean Implementation |

|---|---|---|

| Inventory Levels | High | Reduced |

| Lead Times | Long | Shortened |

| Storage Costs | Significant | Lowered |

| Waste | Considerable | Minimized |

Adopting lean principles is a strategic move that aligns with efficient supply chain management strategies such as JIT inventory, cross-docking, and technology integration, ultimately leading to scalability and improved profitability.

Just-In-Time Inventory to Reduce Waste

The Just-In-Time (JIT) inventory strategy is a cornerstone of lean management, focusing on reducing waste and enhancing efficiency. By receiving goods only as they are needed for production or sales, companies can significantly cut storage costs and minimize the risk of obsolescence. This approach aligns closely with customer demand, ensuring that inventory levels are optimized without excess stockpiling.

The electronics industry provides a clear example of JIT’s effectiveness. Manufacturers can streamline their operations by ordering components precisely when needed for assembly, thus avoiding the pitfalls of overstocking and reducing unnecessary storage expenses.

The benefits of JIT are not limited to cost savings; they also include:

- Improved inventory turnover

- Enhanced production flow

- Reduction of excess inventory

- Better alignment with customer demand

Implementing JIT requires careful coordination with suppliers to ensure timely delivery of components, which is critical for maintaining production continuity without the need for large inventories.

Using Predictive Analytics to Manage Stock Levels

The integration of AI-driven predictive analytics is transforming supply chain management. By analyzing historical data and identifying trends, businesses can forecast demand with greater accuracy, leading to optimized inventory levels and reduced carrying costs. Predictive analytics not only anticipate potential disruptions but also allow for proactive measures to minimize their impact, ensuring efficient operations and resilience.

- Example: An electronics manufacturer analyzes historical sales data and weather patterns to optimize inventory levels during peak seasons.

Predictive modeling is instrumental in achieving a balance that maintains a lean inventory while meeting customer demands promptly.

Collaborative forecasting further refines this process. By working with sales teams, customers, and suppliers, companies can enhance their forecasting accuracy. A retailer, for instance, can collaborate with suppliers to ensure the right amount of stock for each season, thus minimizing excess inventory.

Leveraging E-Commerce for Supply Chain Efficiency

Integrating Omnichannel Fulfillment Systems

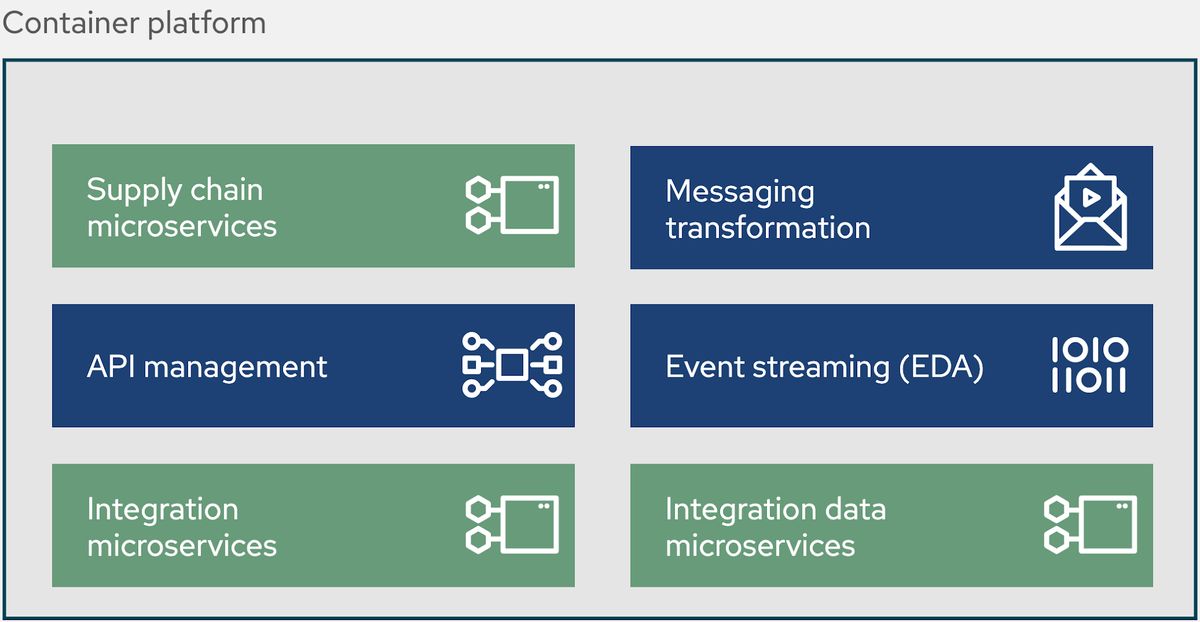

In the realm of supply chain management, the adoption of omnichannel fulfillment systems marks a significant stride towards operational efficiency. These systems serve as a unified platform, centralizing the management and analysis of supply chain data, which in turn empowers businesses to refine their processes and swiftly adapt to supply chain dynamics.

The seamless integration of various supply chain functions—such as inventory management, order processing, and logistics—through advanced technology solutions like ERP software, is pivotal for achieving real-time visibility and control.

While the benefits are clear, companies must navigate potential challenges:

- Integration and Compatibility Issues: Ensuring different technology systems work together without data inconsistencies or operational complexities.

- Security and Privacy Concerns: Safeguarding sensitive supply chain data against breaches and unauthorized access.

By addressing these challenges and leveraging automation, businesses can enhance inventory turnover, reduce lead times, and minimize manual errors, setting the stage for a more responsive and resilient supply chain.

Automating Order Processing with E-Commerce Tools

The integration of automated order processing systems is a game-changer for e-commerce businesses, significantly reducing lead times and enhancing accuracy. Automation not only streamlines the workflow but also minimizes the potential for human error, leading to a more reliable supply chain.

By leveraging technologies such as robotic process automation (RPA) and enterprise resource planning (ERP) systems, companies can achieve a higher level of operational efficiency. These tools are instrumental in managing large volumes of orders, updating inventory records in real-time, and ensuring that products are shipped swiftly to meet customer expectations.

The benefits of automation are further amplified when combined with predictive analytics, which anticipates customer demand and adjusts warehouse operations accordingly. This proactive approach to order fulfillment is essential for maintaining a competitive edge in the fast-paced world of online retail.

Exploiting Dropshipping to Minimize Inventory Costs

Dropshipping has emerged as a transformative strategy for businesses looking to reduce inventory costs. By leveraging the dropshipping model, companies can eliminate the need to maintain large stockpiles of products, instead relying on suppliers to ship items directly to customers. This approach not only cuts down on storage and handling expenses but also mitigates the risks associated with overstocking.

Key benefits of dropshipping include:

- Reduced capital investment in inventory

- Lower storage and warehouse costs

- Flexibility to offer a wider range of products

- Enhanced scalability to meet fluctuating demand

Dropshipping aligns perfectly with the modern need for lean and agile supply chain practices. It allows businesses to respond quickly to market changes without the burden of excess inventory.

While dropshipping offers numerous advantages, it’s crucial to partner with reliable suppliers and have a robust system for order management to ensure customer satisfaction. The success of this model hinges on the seamless integration of supplier and retailer operations.

Continuous Improvement and Agile Adaptation

Embracing a Culture of Continuous Improvement

In the realm of supply chain management, continuous improvement is not just a goal; it’s a necessity. By fostering a culture that values learning and innovation, companies can stay ahead of the curve in a rapidly evolving market. This involves championing continuous learning and encouraging employees to stretch beyond their comfort zones.

Embracing digital transformation involves more than just adopting new technologies; it’s about nurturing a mindset that values innovation and views failure as a learning opportunity.

To operationalize this culture, businesses can:

- Analyze processes to identify areas for improvement

- Implement changes based on data-driven strategies

- Encourage risk-taking and view setbacks as stepping stones

By soliciting feedback from all stakeholders, including employees and customers, and integrating their insights into the business strategy, companies can create a dynamic environment that thrives on feedback and adapts to new challenges.

Implementing Agile Methodologies in Supply Chain Operations

In the realm of supply chain management, agility is paramount for businesses to thrive in a dynamic market. The adoption of agile methodologies enables companies to streamline material flow, minimize inventory, and enhance overall supply chain efficiency. For instance, electronics manufacturers often use lean principles to minimize product defects and lead times, which is a testament to the effectiveness of agile practices.

By implementing agile methodologies, businesses can achieve faster inventory turnover and improve the average age of inventory performance. This strategic approach is crucial for staying competitive in today’s fast-paced business environment.

Moreover, businesses need to use analytical methods and tools that can help them model, simulate, and evaluate various scenarios and alternatives in the supply chain. This analytical approach, coupled with continuous improvement techniques such as lean, six sigma, and agile, can help eliminate waste, reduce variation, and increase flexibility.

- Enhanced agility and responsiveness

- Streamlined material flow

- Minimized inventory levels

- Reduced costs and improved operational efficiency

Logistics websites must adapt to market changes and offer scalable solutions for diverse customer needs to stay competitive and innovative in the digital landscape.

Case Study: Zara’s Fast-Fashion Supply Chain Model

Zara’s approach to supply chain management exemplifies how agility and rapid response to market trends can lead to industry dominance. Their ability to go from design to store in a matter of weeks is a testament to their highly streamlined operations. By continuously assessing market data, Zara adjusts production schedules to align with current fashion trends, ensuring that their inventory is both fresh and in demand.

The key to Zara’s success lies in its integrated supply chain, where communication and efficiency are paramount. This integration allows for a seamless flow of information, which is critical in the fast-paced world of fashion retail.

- Risk Mitigation: Zara diversifies its sourcing and maintains safety stock to buffer against supply chain disruptions.

- Continuous Improvement: Regular assessments and adaptability are ingrained in Zara’s operational ethos, contributing to a robust and responsive supply chain.

- Market Responsiveness: Real-time analytics enable Zara to capitalize on emerging trends, translating into increased sales opportunities.

In the fast-paced world of logistics, continuous improvement and agile adaptation are not just buzzwords—they are essential strategies for success. At MasteringAgency.com, we specialize in creating custom logistics websites and marketing solutions that help you stay ahead of the curve. Our strategic, data-driven approach ensures that your logistics company gains a competitive advantage, improves efficiency, and achieves long-term success. Ready to transform your digital presence and drive real results? Visit our website and book your FREE consultation today!

Conclusion

In the quest for operational excellence, cutting-edge websites have emerged as pivotal tools in revolutionizing supply chain management. By harnessing advanced tracking technologies, optimizing inventory levels, and implementing effective demand management techniques, these platforms enable businesses to navigate the complexities of today’s market with agility and precision. The success stories of companies like Zara underscore the transformative impact of streamlining supply chain processes, leading to reduced costs, improved efficiency, and heightened customer satisfaction. As organizations continue to embrace these innovative strategies, they not only enhance their supply chain efficiency but also secure a competitive edge in an ever-evolving business landscape.